Your 101 On Aggregates

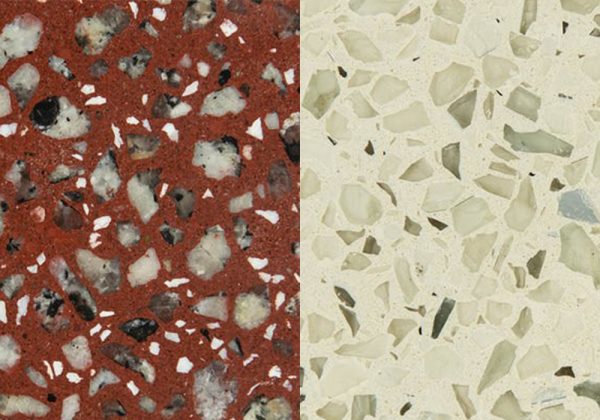

Aggregates can be considered the silent heroes of a resin flooring job. Yes, the chemistry of the resin product itself is of the utmost importance. However the great look of the flooring is achieved because of the aggregates that are mixed in the compound. This insight is to shed light on aggregate and show you its importance in the field of resin and the aesthetic look of the interiors when used it correctly. What are Aggregates? Aggregate is a term used to describe pieces of broken or crushed rocks, minerals, stones that are generally used in concrete of building and construction work. Terrazzo is quite versatile; it can accommodate all kinds of different chips depending on how you would like the aesthetic appeal. It can be either granite, flint, glass or other small chips and variation in size. Aggregate tells us a lot regarding interior spaces, where we can create bright and glittering, classic and traditional or a contemporary modern touch. Terrazzo is an ancient concept, however today’s technology with the use of resin has brought in a wide range of aggregates that can be added such as marble, quartz, concrete, porcelain and metal, all combined to create a perfect smooth finished floor. Using aggregates such as recycled glass and other materials helps to reduce the amount of waste taken to landfill and hence is a sustainable choice. Depending on the aggregate and the quantity being used, it can play major role on factors such as durability, lifespan and cleanability of the floor. Aggregate Sizes Picking the right aggregate size can be tricky especially as each comes in different shapes and sizes. Crushing techniques usually make a range of different sizes altogether of the chips being used. A cone crusher will reduce the aggregate in size and produce rounded edge whereas a jaw crusher creates a more elongated shape with a jagged outline. To help give you an idea on how this looks like, here are 2 examples we have showcased below; In the first example, aggregates are granite and flint pieces ranging from 1.5-5mm In this next picture, the aggregates are clear glass pieces ranging from 1-5mm We hope that this has helped you understand aggregates a little better. To get in an in-depth look on our work and to speak to an expert, please feel free to get in touch with us.